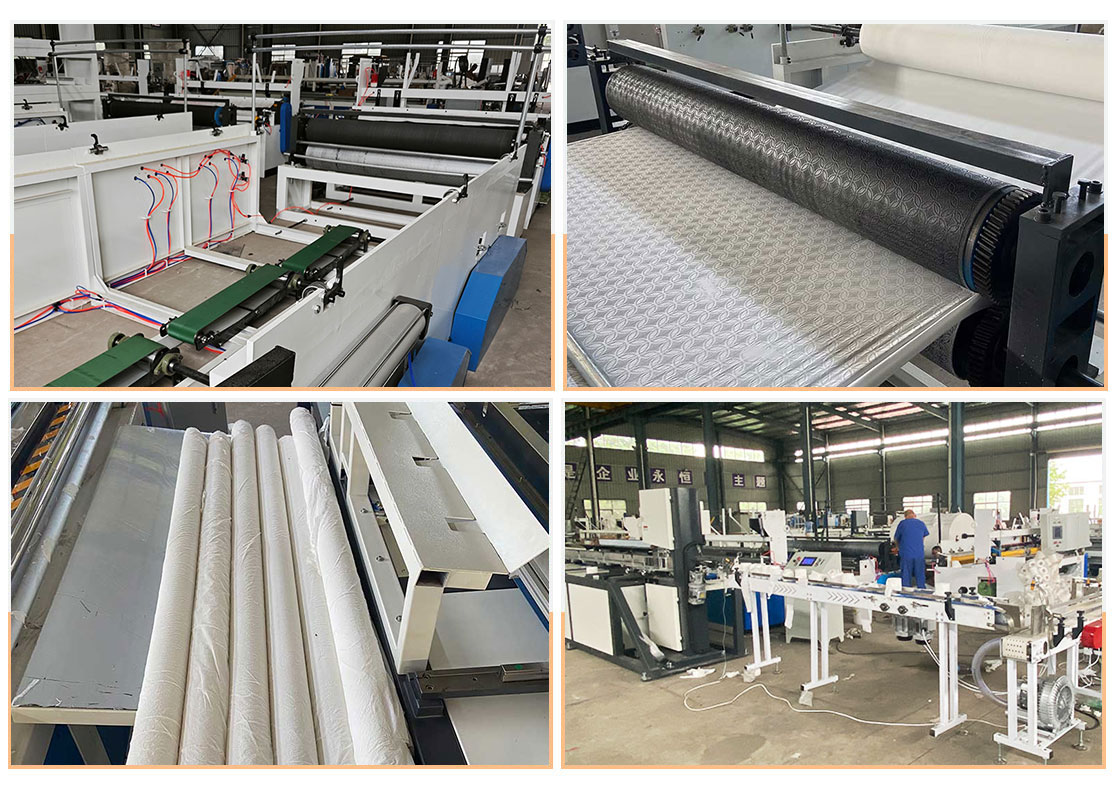

Toilet Paper Rewinder Machine

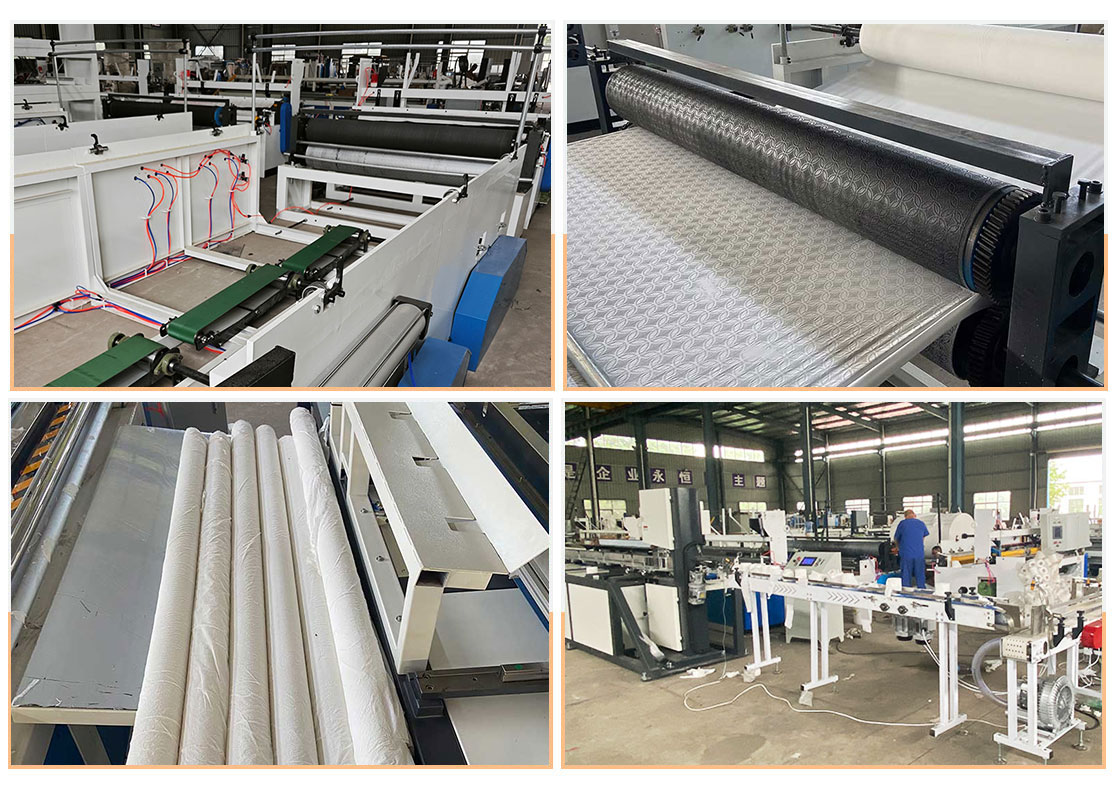

Toilet paper rewinder is a key equipment in the toilet paper production process. It is mainly used to rewind, slit, trim, spray glue, seal and other operations on the large roll paper raw materials to make them into toilet paper rolls that meet the market sales specifications.

-

1.High Production Efficiency: The processing speed of the fully automatic toilet paper rewinding machine can reach 125 meters - 185 meters / minute.

-

2.Fully Automatic vs. Semi-Automatic: The fully automatic model can automatically complete multiple processes, reduce manual intervention, and the product quality is stable; the semi-automatic model has a lower cost, but there are more manual operation links.

-

3.Good Product Quality: Through precise tension control and rewinding technology, the tightness of the toilet paper roll is uniform, the appearance is smooth, and embossing, punching and other treatments can be performed to increase the added value of the product.

Toilet Paper Display

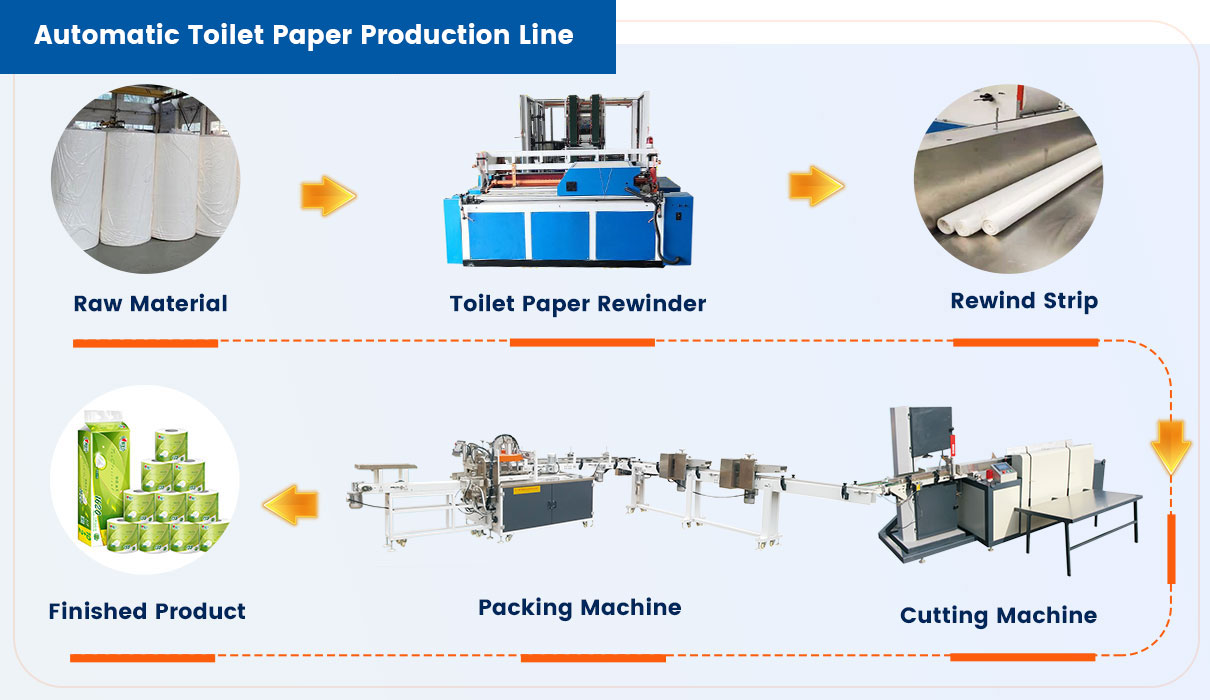

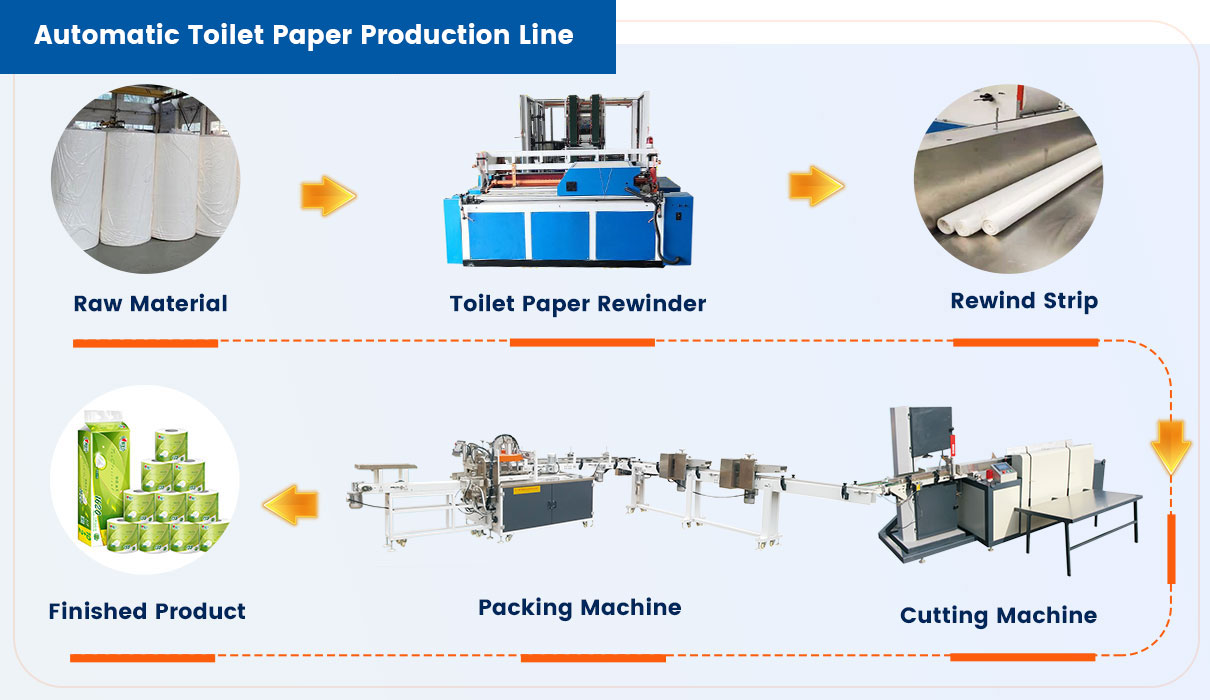

Fully Automatic & Semi-Automatic Toilet Paper Production Line

The fully automatic toilet paper production line first rewinds the toilet paper mother roll, cuts it into small rolls of toilet paper of appropriate width and length according to demand, and counts it. It can automatically change paper tubes, spray glue, seal edges, trim edges and other operations. Then the rewound toilet paper is cut to meet the requirements of different packaging sizes. Finally, the finished toilet paper is packaged to improve the product's preservation and facilitate transportation and sales. The packaging equipment can automatically complete operations such as bagging, sealing, and labeling.

Compared with semi-automatic or manual production lines, fully automatic production lines require less human intervention. Only a small number of technicians are required to monitor and maintain the equipment, which reduces a lot of manual labor and reduces labor costs. A small semi-automatic production line may require 5-10 people to operate, while a fully automatic production line with the same output may only require 1-2 people.

Customize Your Tissue Production Line

1Output: If you are mainly targeting small local retailers, a lower output (such as dozens of tons per month) may be sufficient; but if you plan to supply large supermarkets or sell across regions, you will need a higher output, perhaps hundreds or even thousands of tons of production capacity per month.

2Labor cost: 2-3 people can complete the work of a fully automatic production line. Also consider the production shift arrangement, whether it is a single shift, double shift or triple shift. Different shift arrangements will affect the production line's operating time and overall production planning.

3Product specifications: paper width and length, number of paper layers, roll diameter and core diameter, etc. These parameters affect the settings of the rewinder and packaging machine.

4Factory planning: semi-automatic production line 50 square meters, fully automatic production workshop 100 square meters.

5After-Sales Service: Yugong provides comprehensive after-sales service, including equipment installation and commissioning, operation training, repair and maintenance, etc. In addition, we also provide equipment accessories to ensure your production needs.

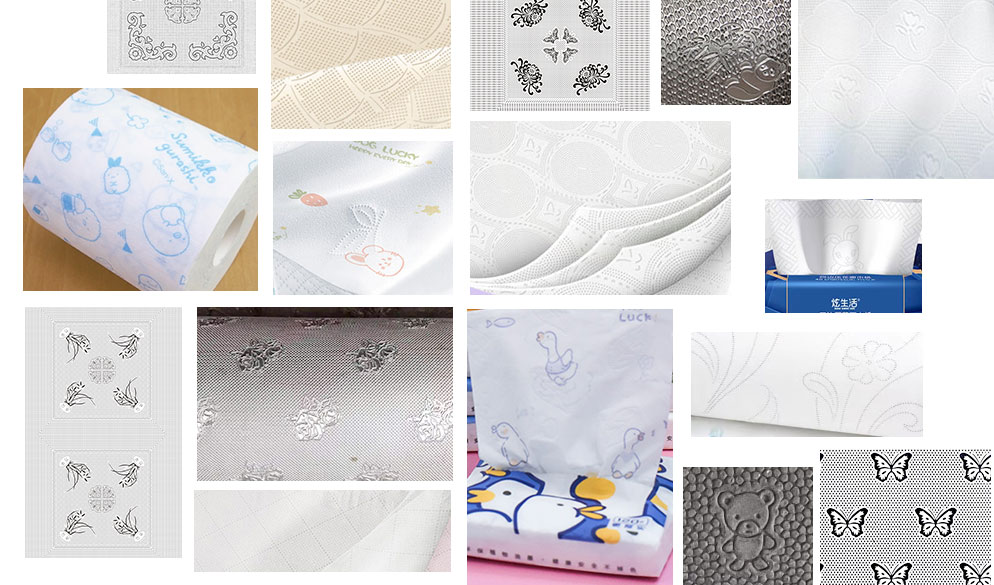

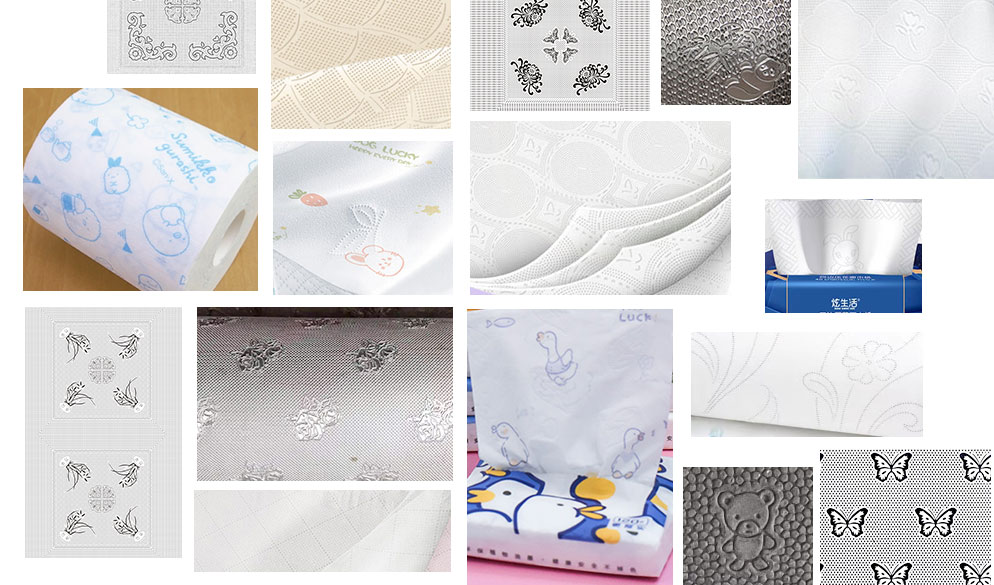

Embossing Pattern Selection

In order for you to quickly find the pattern you like, some are listed below for you to choose from, In addition, you can consult us for exclusive pattern designs.

You May Need

Good Feedback

Good Feedback

Related Products

Related Products